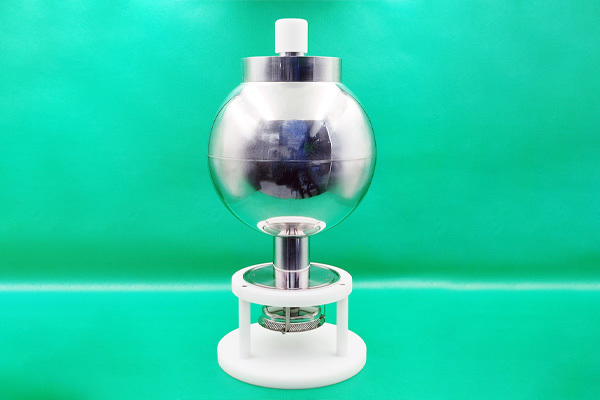

Cold traps are crucial components in vacuum technology, playing a vital role in maintaining the integrity and performance of vacuum systems. These devices are designed to mitigate contaminants that could otherwise compromise the efficiency and longevity of the system. By employing cold traps, operators can ensure that their vacuum systems function optimally, even in the presence of volatile or particulate materials. At its core, a cold trap operates on the principle of condensation. In a vacuum system, the pressure is significantly reduced to create an environment where contaminants, such as water vapor, hydrocarbons, or other volatile substances, are more likely to condense. The cold trap is cooled to very low temperatures, often using liquid nitrogen or helium, creating a surface where these contaminants can freeze out of the gas stream. This process effectively removes impurities from the vacuum environment before they reach sensitive components like pumps or analytical instruments. The effectiveness of a cold trap depends largely on its temperature and design.

This temperature is typically achieved through advanced cooling systems that maintain a consistent low temperature, ensuring that the trap remains effective over extended periods. Additionally, the design of the trap, including factors such as surface area and material composition, influences its efficiency. High surface area traps can capture more contaminants, while materials with better thermal conductivity can enhance the cooling process. GWSI Cold traps are particularly beneficial in high-vacuum and ultra-high-vacuum systems where even trace amounts of contaminants can have significant effects. In these systems, the presence of contaminants can lead to issues such as degradation of vacuum pump performance, contamination of experimental samples, or interference with sensitive measurements. By trapping these contaminants before they reach critical components, cold traps help in preserving the vacuum quality and ensuring reliable performance. One of the key advantages of using cold traps is their ability to protect other components of the vacuum system.

For instance, in mass spectrometry, a cold trap can prevent water vapor from entering the analyzer, which could otherwise lead to incorrect readings or damage to the sensitive equipment. Similarly, in research and industrial applications where precise measurements are crucial, cold traps help in maintaining the accuracy and reliability of results. However, cold traps are not without their limitations. They require regular maintenance to ensure they operate effectively, including periodic defrosting and cleaning to remove accumulated contaminants. Additionally, their cooling systems can be energy-intensive and may require careful management to avoid issues related to energy consumption and system overheating. In conclusion, cold traps are indispensable for maintaining the performance and longevity of vacuum systems by mitigating contaminants. Their ability to condense and capture impurities ensures that vacuum environments remain clean and reliable, which is essential for high-precision applications and sensitive equipment. Despite the need for regular maintenance and energy considerations, the benefits they provide in preserving vacuum quality and enhancing system performance make them a valuable component in vacuum technology.